New Products

Find Steel Arch Building Machine, Roof Panel Curving Machine., Arch Roof Forming Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Delivery Time: | 7 Days |

|---|

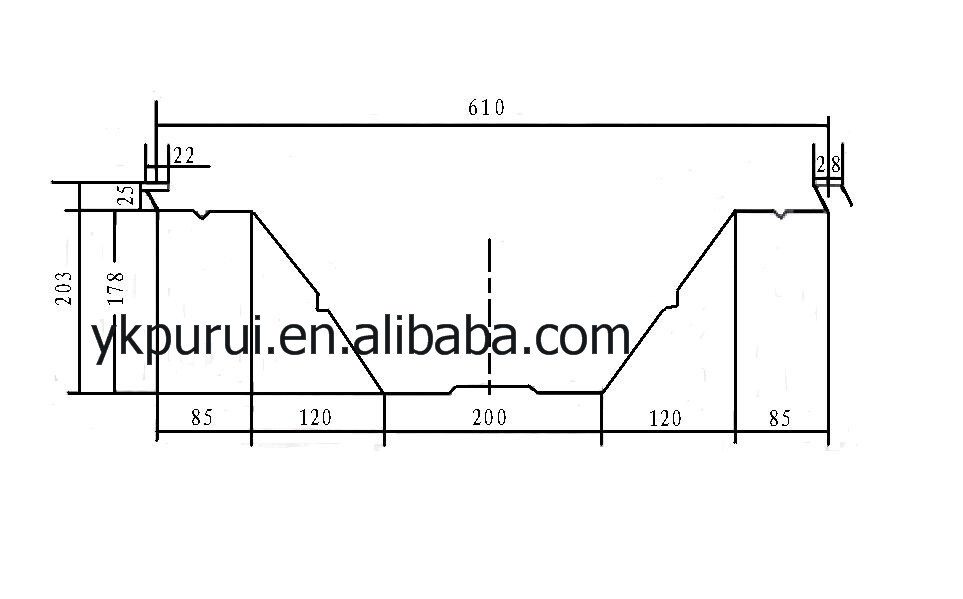

Model No.: PRO914-610/PROABMUBM240

Arch Panel

Arch Panel  Rollers

Rollers  Car chassis with wheels

Car chassis with wheels

Hydraulic cutting

Hydraulic cutting  All machine stronger parts

All machine stronger parts

Technical Parameter of Arch Roof Machine | |

Dimension | 8900mm X 2230mm X 2300mm (Single axle & 4 tires) |

Total Weight | About 8Ton |

Bending Leaf | 10mm thickness, processed by CNC |

Cutting blade | 12CrMoV material, Heat treatment |

Cutting type | Mechanical Cutting |

Forming type | Roll-formed and length-set cutting. |

Total motor power | 17.5KW |

Main Motor Power | 7.5KW |

Bending Power | 3.0KW+1.5KW x 2 |

Cutting Power | 4.0KW |

Seaming Power | 1.1KW+1.1KW |

Roller Material | 45# high-quality steel, quenched HRC 55~65, hard chrome plating. |

Shaft Material | 45# high-quality steel, galvanized |

Bearing | Made in Harbin |

Stand of molding | 13+1 |

Depth of the groove | 203mm |

Rolling material width | Feeding width :914mm |

Effective width : 610mm | |

Using rate | 66.7% |

Thickness | 0.8-1.5mm |

Working Speed | 15m/min |

Bending Part | 13m/min |

Seaming | 16m/min |

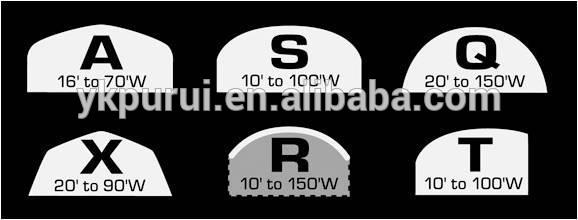

Suitable width | 6-38m |

De-coiler | Inner-diameter of coil : 450mm ~ 650mm |

| Max width of coil : 914mm ~ 934mm |

| Load : 10Ton |

| Name | Amount | Usage |

| Manual De-coiler | 1 | Coil support & De-coil |

Seaming machine | 2 | Assemble the finished arches |

| Run out table | 20 | Sheet support |

Leg of run out table | 19 | Support run out table |

Small leg of run out table | 48 | Adjust the height of run out table |

| Fastening screw for leg | 58 | Fastening leg |

Side support | 10 | Sheet support |

| Suspender | 3 | Lifting |

| Pin of suspender | 2 | Connect the suspender |

| Hanger | 8 | Lifting |

| Clamp | 4 | Bite finished arches |

| Bearing(208#) | 4 | Drive the rollers |

| Driving chain | 3(run) | Roll the gears |

| Chain link | 3 | Link the chain |

| Half section | 3 | Link the chain |

| Super plier | 1 | Bite finished arches |

| Metal scissor | 1 | For cutting |

| Wrench | 1 | For set screw |

| Crank handle | 2 | Adjust height of landing leg |

| Travel switch | 1(suit) | Measure length for cut-to-length |

| VCD | 2 | Showing how to operate the machine Showing how to make project |

Suitable Type list

Suitable Type list | Model | Feeding width (mm) | Effective width (mm) | Depth of groove (mm) | Utilization ratio | Thickness of steel coil (mm) | Largest span (m) |

PRO-600-305 | 600 | 305 | 109 | 50.8% | 0.6-1.5 | 24 |

PRO-600-300 | 600 | 300 | 100 | 50% | 0.6-1.5 | 24 |

| PRO-914-400 | 914 | 400 | 210 | 43.7% | 0.6-1.5 | 40 |

| PRO-914-610 | 914 | 610 | 203 | 66.7% | 0.6-1.5 | 38 |

| PRO-914-650 | 914 | 650 | 181 | 71.1% | 0.6-1.5 | 26 |

| PRO-914-700 | 914 | 700 | 123 | 76.5% | 0.6-1.5 | 2 |

| PRO-914-750 | 914 | 750 | 180 | 82% | 0.6-1.5 | 14 |

| PRO-1000-610 | 1000 | 610 | 243 | 61% | 0.6-1.5 | 42 |

| PRO-1000-680 | 1000 | 680 | 223 | 68% | 0.6-1.5 | 38 |

| PRO-1000-700 | 1000 | 700 | 175 | 70% | 0.6-1.5 | 30 |

| PRO-1000-750 | 1000 | 750 | 138 | 75% | 0.6-1.5 | 24 |

| PRO-1000-800 | 1000 | 800 | 114 | 80% | 0.6-1.5 | 18 |

| PRO-1200-800 | 1200 | 800 | 265 | 66.7% | 0.6-1.5 | 42 |

| PRO-1220-800 | 1220 | 800 | 277 | 65.5% | 0.6-1.5 | 44 |

| PRO-1250-800 | 1250 | 800 | 320 | 64% | 0.6-1.5 | 45 |

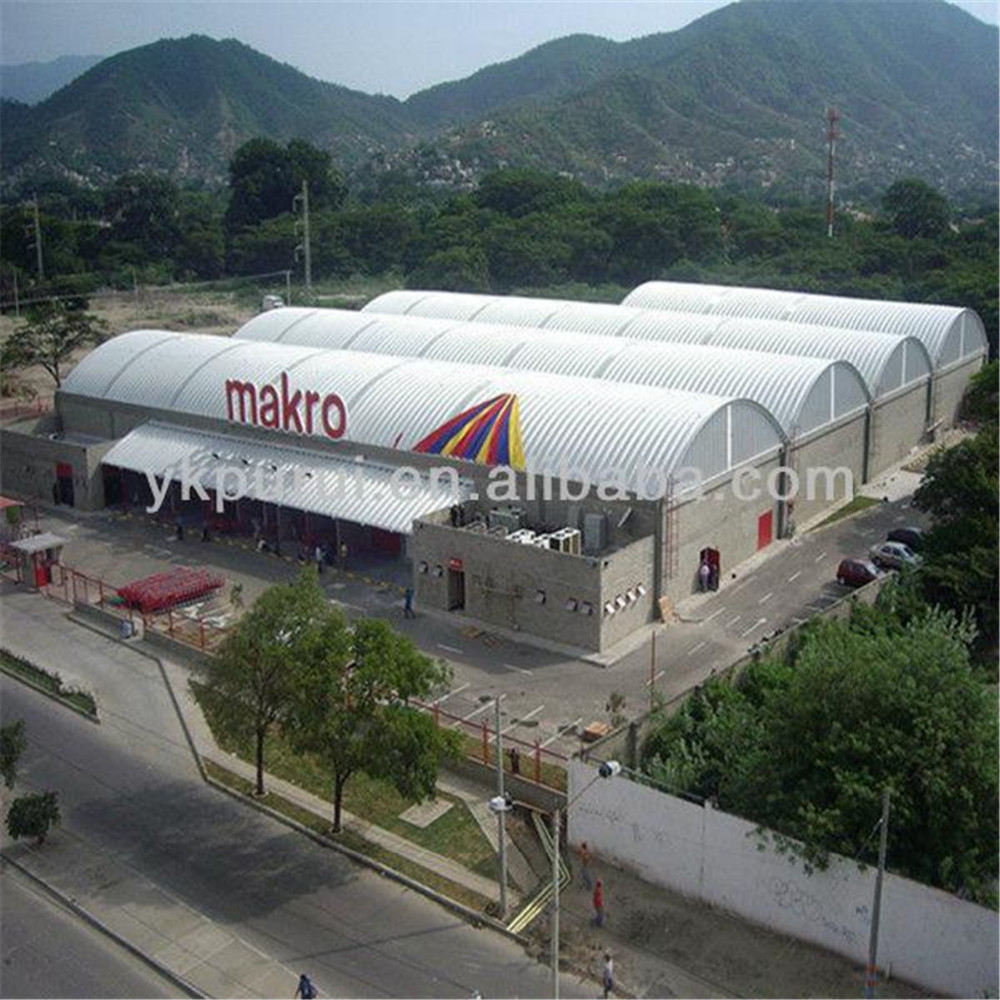

Other project

Other project  Packaging&shipping: Naked by vessel 1*40HQ

Packaging&shipping: Naked by vessel 1*40HQ  Company information:

Company information:  FAQ Q: Are You the factory or trade company? A:We are the factory,found in 2000, Q: Can you make the machine according to my demand? A: Yes. we have professional team and development personnel can plan to the suitable designs you need. Q:What's the MOQ? A:One set, more should be discount. Q:What's the type of payment? A: 30% T/T in advance,70% T/T before shipment Q:Why we choose you of all the same industry? A:Our company have competitive quality and price in the whole industry,welcome to you visit any time. Our Services Q: Do you have longlife after-sales service support? A: Yes, our machine warranty period is 13 months, and support lifelong service. B:We can offer 24 hours line service. Our company Introduce Main products are:Steel-drum production line,steel drum,PRO-240/PRO-120 Arch Sheet Roll Forming Machine, Multi-shape Building Machine,Screw-jointed Equipment,Arch Sheet Project,MSBM Project, Screw-jointed Project,KR Series Roll Forming Machine,Glazed tile Roll Forming Machine,Double Layer Roll Forming Machine,840 Corrugated Sheet Roll Forming Machine,Corrugated Roof Sheet Forming Machine, Concealed Roof Sheet Forming Machine,Steel Decking Roll Forming Machine,C/Z/U/M Machine,Lifting Machine, Unlimited Length Ridge Tile Forming Machine,Sheering Machine,Window and Door Taping machine, Flat Sheet Bending Machine,Pipe Bender Machine,Bending Machine,Slitting Machine,Slitting Line, SM-40 Spiral Steel Silo Forming Machine,PU Spray and Perfusion Equipment,Colored Steel Sheet Coils,etc.

FAQ Q: Are You the factory or trade company? A:We are the factory,found in 2000, Q: Can you make the machine according to my demand? A: Yes. we have professional team and development personnel can plan to the suitable designs you need. Q:What's the MOQ? A:One set, more should be discount. Q:What's the type of payment? A: 30% T/T in advance,70% T/T before shipment Q:Why we choose you of all the same industry? A:Our company have competitive quality and price in the whole industry,welcome to you visit any time. Our Services Q: Do you have longlife after-sales service support? A: Yes, our machine warranty period is 13 months, and support lifelong service. B:We can offer 24 hours line service. Our company Introduce Main products are:Steel-drum production line,steel drum,PRO-240/PRO-120 Arch Sheet Roll Forming Machine, Multi-shape Building Machine,Screw-jointed Equipment,Arch Sheet Project,MSBM Project, Screw-jointed Project,KR Series Roll Forming Machine,Glazed tile Roll Forming Machine,Double Layer Roll Forming Machine,840 Corrugated Sheet Roll Forming Machine,Corrugated Roof Sheet Forming Machine, Concealed Roof Sheet Forming Machine,Steel Decking Roll Forming Machine,C/Z/U/M Machine,Lifting Machine, Unlimited Length Ridge Tile Forming Machine,Sheering Machine,Window and Door Taping machine, Flat Sheet Bending Machine,Pipe Bender Machine,Bending Machine,Slitting Machine,Slitting Line, SM-40 Spiral Steel Silo Forming Machine,PU Spray and Perfusion Equipment,Colored Steel Sheet Coils,etc.Product Categories : Arch Roof Roll Forming Machine