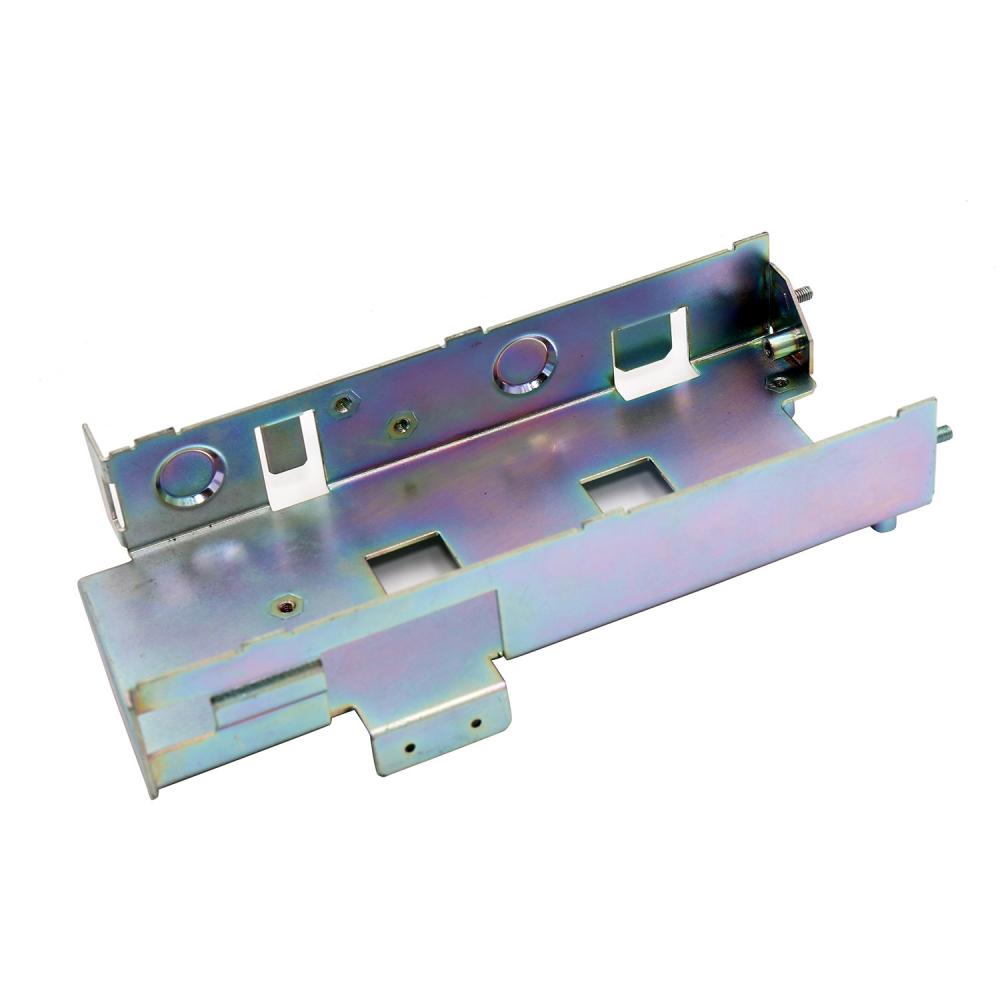

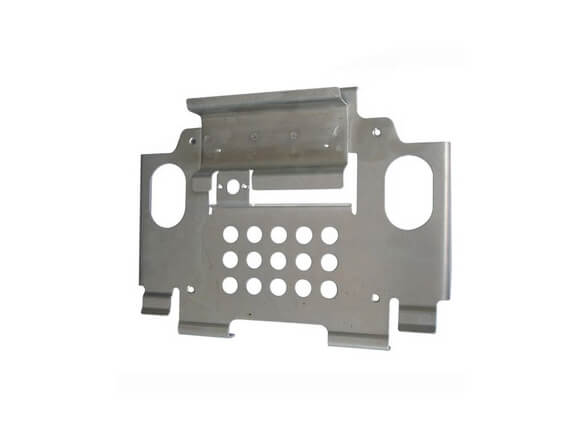

New Products

Find Sheet Metal Cabinet, Metal Sheet Stamping Parts, Auto Stamping Parts on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Unit Price: | 6 USD |

|---|---|

| Min. Order: | 10 Piece/Pieces |

Usually, the three most important steps in a sheet metal factory are shearing, punching / cutting and folding. Modern sheet metal processes include: filament power winding, laser cutting, heavy processing, metal bonding, metal drawing, plasma cutting, precision welding, Roll Forming, sheet metal bending, die forging, water jet cutting, etc.

In 3D software, Solidworks, UG, Pro / E, SolidEdge, topsolid, etc. all have sheet metal parts, which mainly obtain the data required for sheet metal parts processing (such as unfolded drawing, bending line, etc.) through the editing of 3D graphics, as well as CNC punching machine / laser, ion, etc Data are provided by laser, plasma, waterjet cutting machine / combination machine and CNC bending machine.

In addition to the strict requirements in the production process, the quality of sheet metal parts requires quality inspection independent of production. First, strictly control the size according to the drawing, and second, strictly control the appearance quality. Repair or scrap the inconsistent size. The appearance is not allowed to be scratched, and the color difference, corrosion resistance and adhesion after spraying are inspected. In this way, we can find the errors in the expansion drawing, bad habits in the process, and errors in the process, such as digital punch programming errors, mold errors, etc.

According to your drawings (size, material, thickness, processing content, required technology, etc.)

Material: carbon steel, SPCC, SGCC, stainless steel, aluminum, brass, copper, etc

Processing: Laser cutting, precision stamping, bending, CNC punching, grinding, riveting, drilling, welding, and so on

Surface treatment: drawing, polishing, anodizing, powder coating, electroplating, screen printing, sandblasting, etc

Tolerance: ±0.1mm, 100%QC before delivery, can provide quality control table

Size: Accept custom size.

Colors: white, blank, silver, red, gray, Pantone, RAL, etc

Drawing format: DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, draft.

Price terms: EXW, FOB, CIF, DDP, etc

Payment term: Sample: 100% payment before production

Mass production :(50% in advance as deposit, balance before delivery)

Certificate: ISO9001:2015 / SGS

Q1: Are you a factory or a trading company?

A: We are a factory, so we can offer you competitive prices.

Q2: What kind of services do you offer?

A: OEM sheet metal processing, CNC processing, stamping tool manufacturing, etc.

Q3: What information is required for a quotation?

A: In order to quote for you earlier, please provide us with the following information at the time of inquiry.

1. Detailed drawings (STEP,CAD,SOLID Works,DXF,PDF)

2. Material requirements (SUS,SPCC,AL,SECC,SGCC)

3.Surface treatment(powder coating,planting,sand blasting,polishing,oxidization,brushing,etc)

4. Quantity (per order/month/year)

5. Any special requirements or requirements, such as packaging, delivery, labeling, etc.

Q4: What if there are no drawings?

A: Please send your sample to our factory, then we can copy or provide you with a better solution, please send us pictures or sketches with dimensions (thickness, length, height, width), if the order is placed, CAD or 3D files will be made for you.

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

Product Categories : CNC Turning > Custom Turning Parts