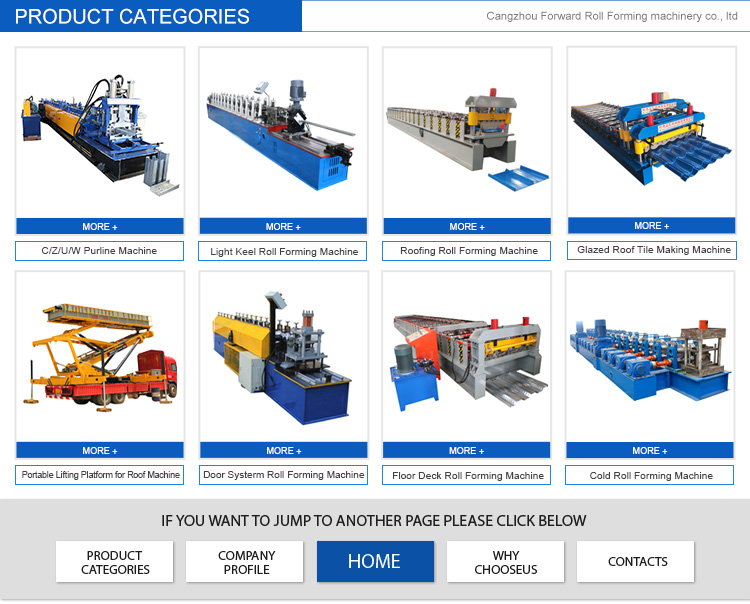

New Products

Find Light Gauge Steel Frame Cold Roll Forming Machine, Drywall Cd Cw Profile Cold Roll Forming Machine, Steel Profile Roll Forming Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Min. Order: | 1 Set/Sets |

|---|

Light gauge steel keel roll Forming Machine key parameters | |

| Suitable material | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

| Thickness of coil sheet | 0.2-0.6mm |

| Usage | Light steel keel |

| Effective width | 75mm |

| Material of main frame | 600H steel |

| Diameter of Soild shaft | 70mm, high grade 45# steel |

| Roller | High grade 45# steel, quenched and tempered treatment, hard chrome plated 0.05-0.07mm |

| Thickness of middle plate | 16mm, 45# steel plate |

| Forming station | 14rows |

| Drive type | By chain(1.0 inch), link bearing model 6210 |

| Power of main motor | 5.5 kw, Lichao, Shanghai, with reducer |

| Sidewall connection bar | 25mm, zinc plated |

| Forming speed | About 12-18m/min |

| Hydraulic pump station | 4.0 kw, 40# hydraulic oil |

| PLC | DELTA(TAIWAN)/Mitsubishi |

| Material of razor blades | Cr 12, quenching 58-62℃ |

| Frequency converter | It has the advantage of slowing down before cutting, to ensure the length accuracy ±1mm, far better than industrial standard ±3mm. |

| Switch | CHNT |

| Frequency changer | SAJ |

Note: Above is standard parameters.

For latest information, please contact us to ask for.

Customizable machine is available according to your specail requirements.

Please contact us to ask for specific profile drawing catalog.

>>Light gauge steel keel Roll Forming machine equipment parts

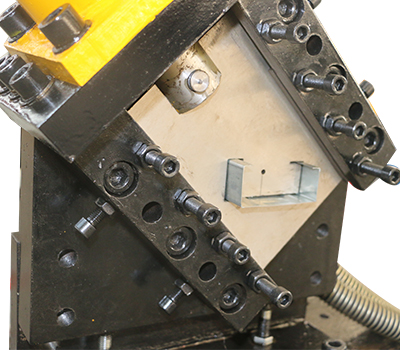

| Roll forming system | |

| Roller station | 12 Steps+3Straighting rollers | |

| Shaft Diameter | 50mm-0.01mm with Key-way | |

| Roller Material | Cr12 with key-way | |

| Heat Treatment | Vacuum quenching upto hardness 58 | |

| Fine Machining | CNC Lathe after vacuum quenching | |

| Machine Structure | 5mm under-frame and 20mm worktable | |

| Motor Power | 5.5KW with PM250(or K-type )Reducer | |

| Transmission Method | All gear with high frequency quenching | |

| Memorial Gateway | 25mm thickness A3 Plate | |

| Gateway Process | Square side with fly edge machine | |

| Production Speed | 30-40m/min | |

| Hydraulic cutting system |  | |

| Cutting Method | Full-auto hydraulic servo-tracking cutting | |

| Hydraulic System | 5.5KW(if hot-weather with water-cooling) | |

| Speed Adjustment | Frequency Changer Control | |

| Cutter Material | Cr12Mov | |

| Cutter Processing | electric spark,polishing machine and wire-electrode cuttingafter heat-treatment | |

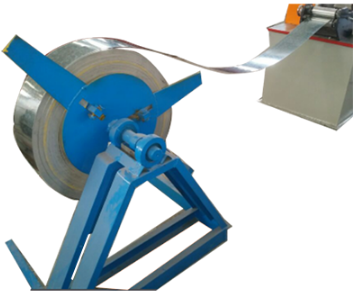

| Decoiler | Receiving Table | ||

| Un-coiler Type | Manual Operation | Total Length | 3000mm |

| Loading Capacity | Max 1500KG | Frame Structure | Angle Steel with Metal Plate |

| Inner Coil Diameter | 460-510mm | Function | Let the finished production freely |

|  | ||

Product Categories : Light Gauge Roll Forming Machine > Partition Keel Forming Machine